HEAVY-DUTY

You Don’t Have a Manpower Problem, You Have a Production Problem

The Gold Standard Since 1976

The Strongest Winch

The Winch is the heart of any elevating scaffold system. One breakdown can cost you thousands. Ours is bullet-proof for years of trouble-free service. Click the winch below to learn more.

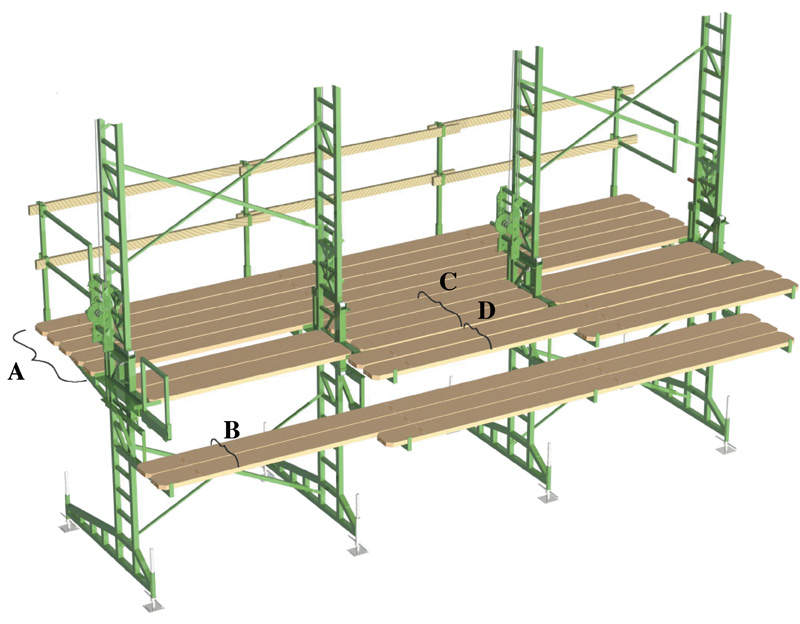

The Strongest Towers

Non-Stop towers are guaranteed never to bend or sway. They’re pre-engineered for exceptional strength, up to 552 feet. Other systems buy their strength by the pound.

The Most Room

The stocking area is five boards wide, with an additional three boards between the towers. Space for full pallets with room to move around them. It’s truly a dance floor in the sky.

Smooth Operation

Aluminum rollers on stainless steel shafts assure that the elevating carriage glides up and down the tower. No binding, rubbing or friction. No other system uses this design.

Constant Safety

Safety is priority #1. Non-Stop’s passive safety system will quickly arrest a fall in the event of a cable failure. It’s automatic, so there’s no locking and unlocking when it’s time to crank.

Scaffolding Accessories for Any Job Condition

From transporting between jobs to setting up cut-up work to working in bad weather, Non-Stop Heavy-Duty Scaffolding has you covered. We’ve designed out all the small parts that tend to get lost.

Rack Brackets

Bundle 10 towers in one 4-foot-wide racks. Two racks fit side by side on any trailer. Leave as many extensions on the bases as you’ve got trailer to haul them.

Read More

Swivel Forklift Bar

Assemble your towers on the ground, then pick them up with the Swivel Forklift Bar. As the name suggests, the bar swivels 60 degrees in each direction.

Read More

Hoist System

The simplest way to raise material to the platform. Rotate the guardrails into place, roll the boards back and bring up the load. Once raised, roll the boards back into place and land the load.

Read More

Inside Corner Bracket

Turning inside corners is no problem. The masons’ walkboards are fully supported right up in the corner with no “diving board” effect.

Read More

Rest Platform

The Rest Platform gives your crew a place to step off the tower to rest while climbing to the work platform.

Read More

Pilaster Plank Support

Add up to three additional walk boards for the masons. The Pilaster Plank Supports can be mounted exactly where you need to support planks.

Read More

21′ Bridge

Use a 21′ bridge anywhere you’ve got an obstruction and can’t land a tower, or need to leave an opening in the wall. The load is never cantilevered and the winches remain easy to crank. At half the cost of a tower, bridges are also an economical way to extend the length of your scaffolding.

Read More

Parts Basket

The simplest way to keep up with braces, guardrail posts and other accessories. Also, there’s an option to use it as a man-basket.

Read More

Barricade Guardrail

Sometimes fall hazards don’t line up with the end guardrails on the scaffold. With the Barricade Guardrail, you can stop a mason’s movement anywhere you need.

Read More

Winter Enclosure

Enclose the entire wall and scaffold in inclement weather. You can even take the enclosure down the back side of the wall as well.

Read More

Overhead Protection

This skeleton lets you decide how you want to enclose just the work platform. It rides up with you as the elevating carriage moves.

Read More

Access Landing

Use the Access Landing when there’s less than 4′ of climbable tower above the work platform. It attaches to the elevating carriage and rides up with you.