The Toughest Winch

The Winch is the heart of any elevating scaffold system. One breakdown stops your entire crew from working. In other words, it‘s got to be the best, the strongest, the most reliable, and with a lifetime warranty.

It must be easy to crank, because if it‘s not, your laborers won’t crank it until they HAVE to. and your bricklayers will be back working from their ankles to their shoulders. At that point, you might as well be back on frames!

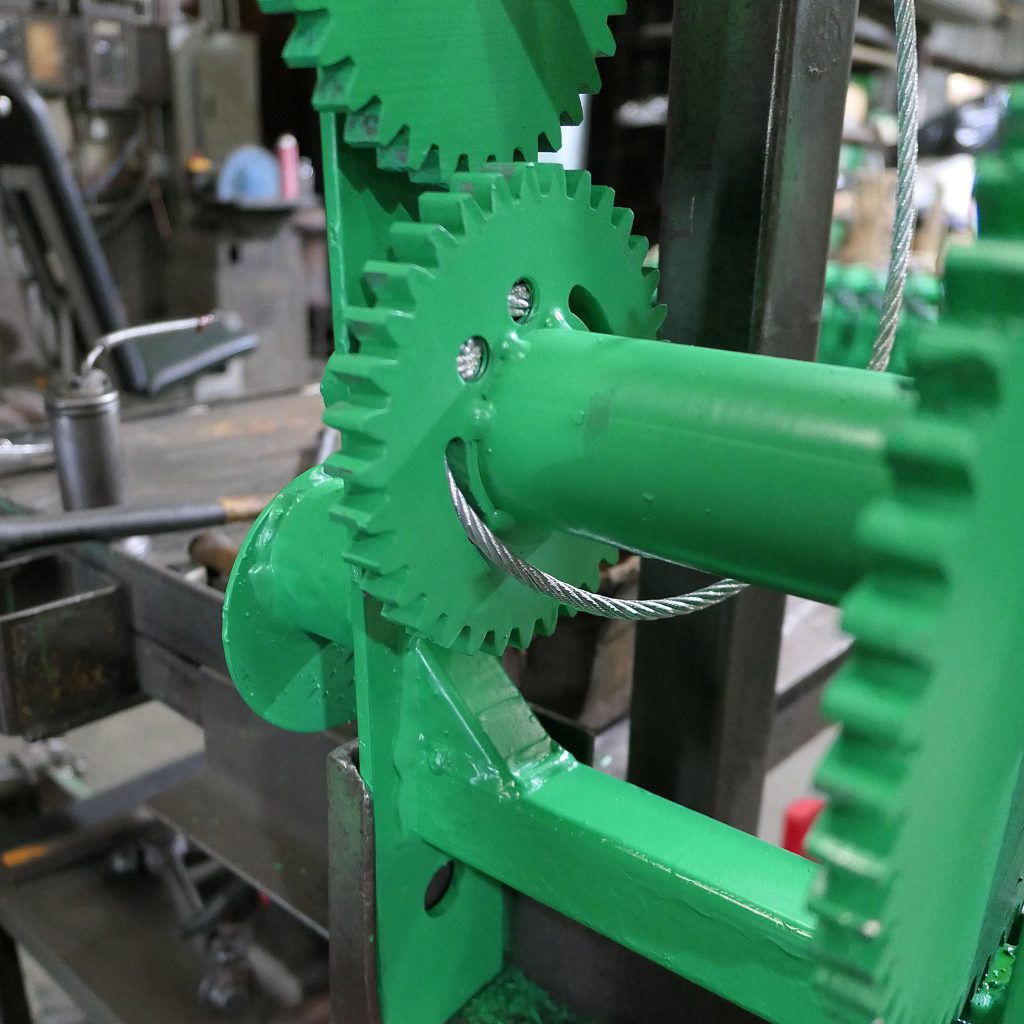

Twice the Cranking Power

The Heavy Duty two-speed winch has twice the cranking power of anything on the market. Many have tried, but no one has yet duplicated the power, quality, and safety you get in the Non-Stop Heavy-Duty winch. You can land a pallet of split-faced 12’s and crank it ONE-HANDED!

No Extra Labor Required!

Use the same labor-to-mason ratio you’re using now on frames. How is this possible? Well just look at everything they’re NOT doing anymore, like hopping plank and raising materials; or tearing down and re-building frames constantly; or cleaning up after running scaffold-high and then building scaffolding. They stay with the masons 100% of the time.

It‘s so easy to crank that two laborers can raise 105 feet of scaffold 16″ (2 courses of block or 5 courses of brick) in about three minutes – leaving tons of time to tend the masons. After a few days, they’ll fall into a routine of cranking for 3 minutes, tending for 20, crank for 3 minutes, tend for 20, all day long. Because that’s ALL they have to do now – raise the scaffold and tend the masons.

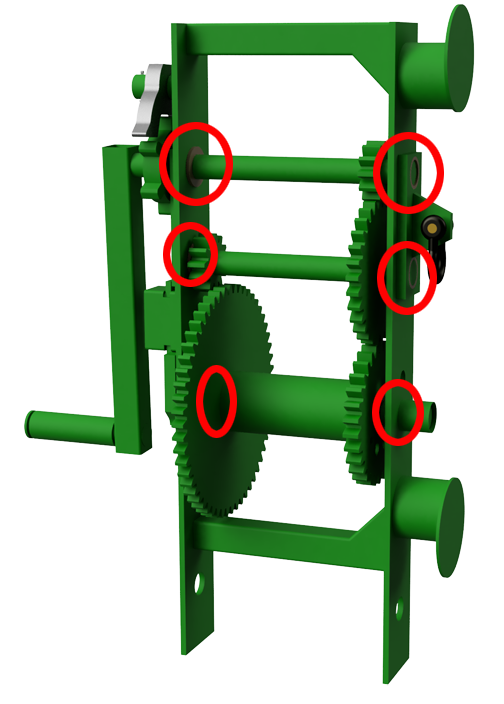

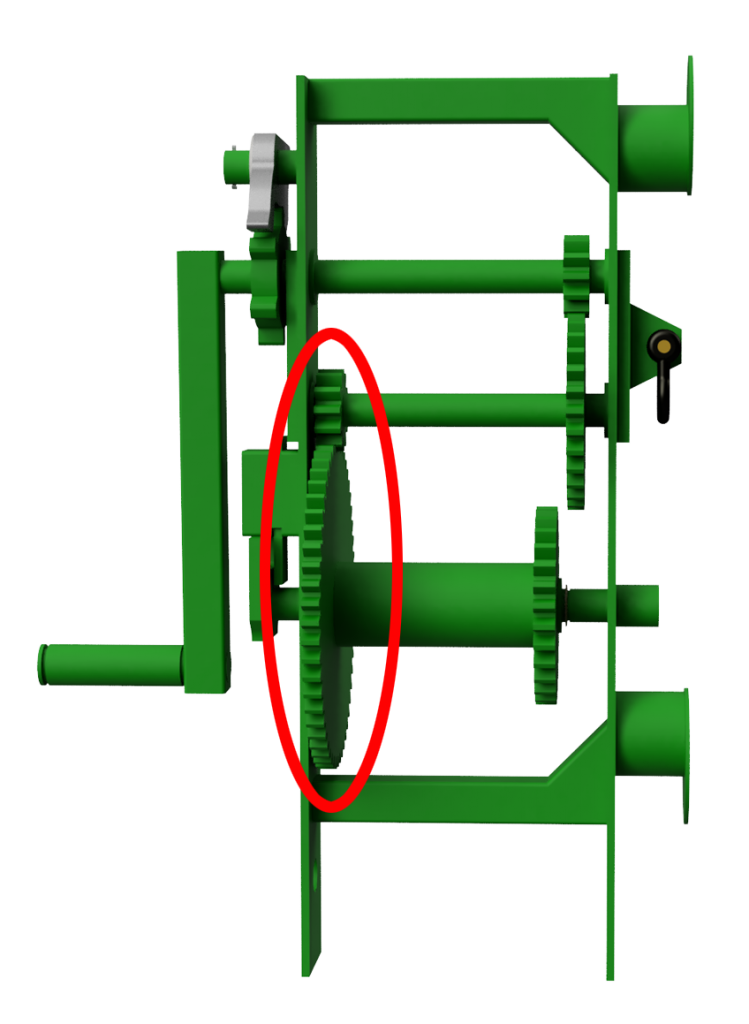

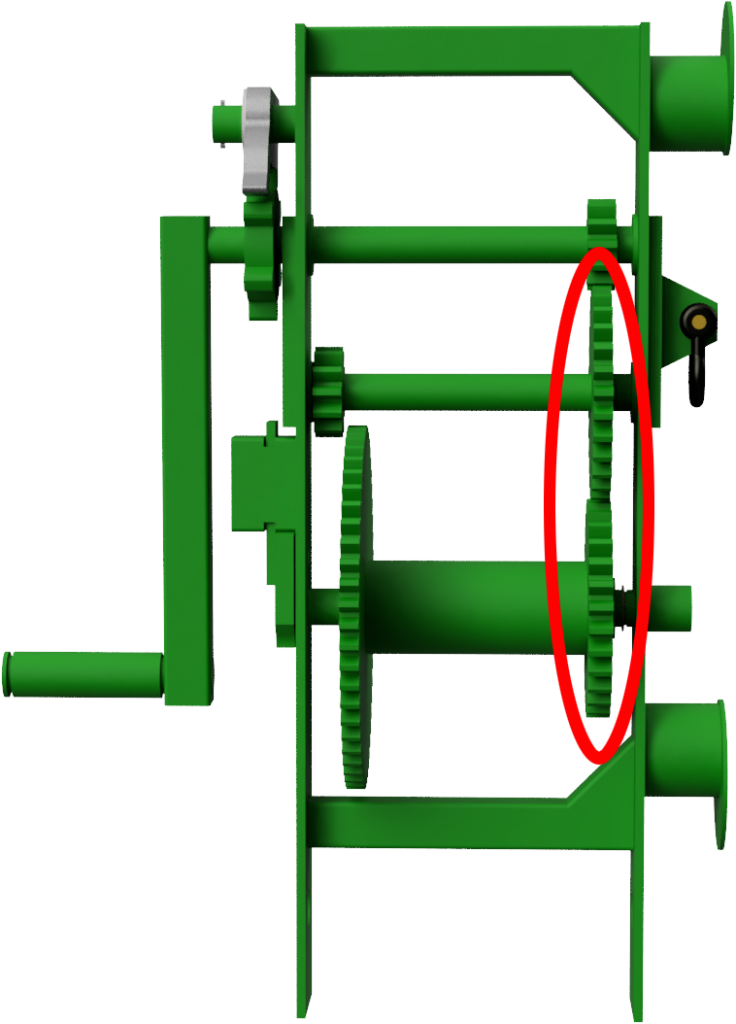

CANNOT Free-Spin

The Double-Acting Safety Dog mechanically keeps the winch handle from free-spinning. Let it go and it LOCKS! It can’t be bypassed. Positive engagement of the dog against the robust 5/8″ thick 6-point wheel means that as soon as the winch handle is released, it locks. Simply turn the handle to resume cranking up.

This anti-reverse safety feature means you must intentionally ride the dog with your free hand to reverse the winch. The scaffold can’t accidentally start lowering and dump the boards as has happened on other systems in the past.

Extremely High Lifting Power

We engineered the winch to offer the lifting power that you require with less effort that you expect. You’ll raise a pallet of block with one hand. Competing systems require two hands and maximum effort just to raise the empty platform, becoming virtually impossible loaded.

High Gear To Get Down Fast

High lifting power is great, but when it’s time to lower the platform and move the scaffold to the next wall, you want to do it fast. Shifting to high lowers the platform 3x faster than it went up.

No Lubrication Required

Self-lubricating bronze bushings provide years of smooth cranking. Wear parts, like the Double Acting Safety Dog and the 6-point wheel it engages are case hardened for maximum durability and long life.

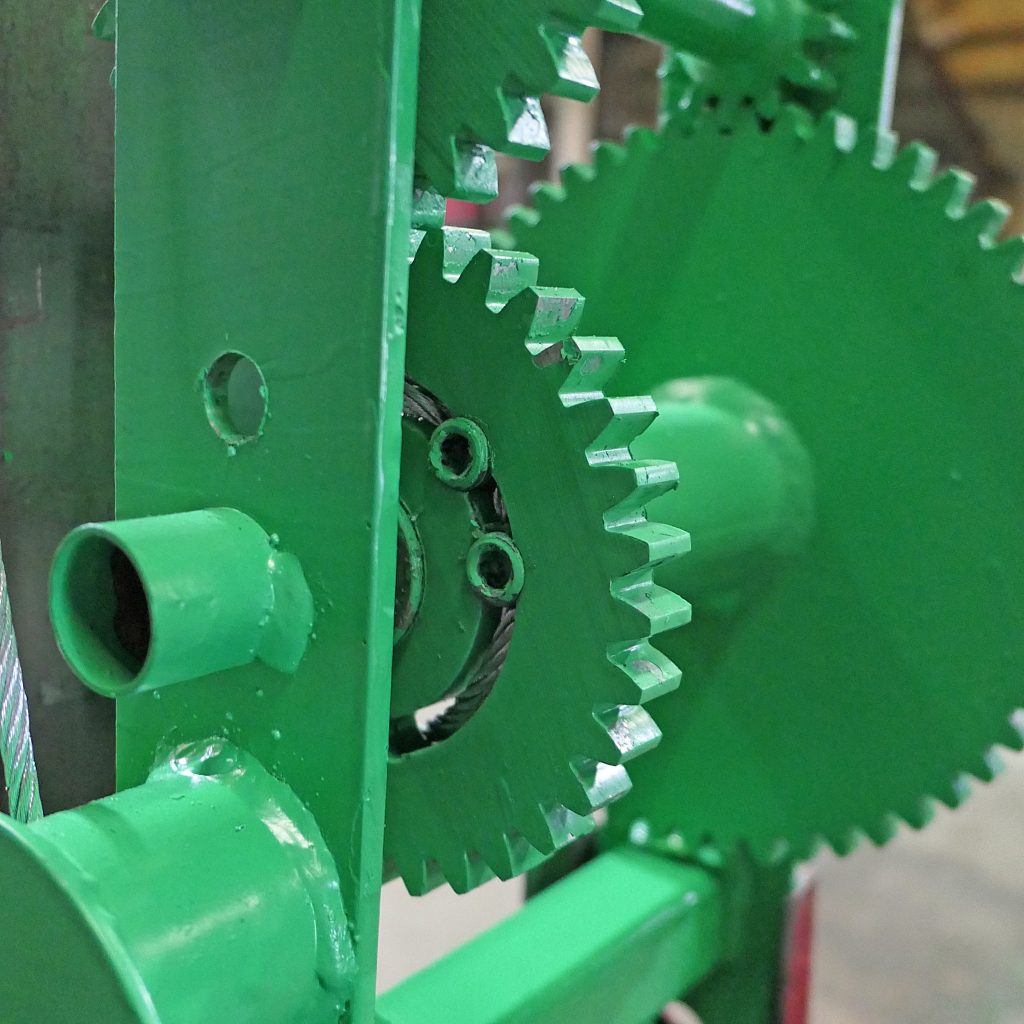

Cable Clamps

Proper cable termination is crucial to get 100% of the strength from your cable rating. Hardware store u-bolts don’t get it.

Since we make our own gears in-house, we can actually machine our cable clamp system into the face of one of the drum gears. It is rated for 100% load carrying capacity.

The Cable Eye

Many cable eyes are simply the end turned back and crimped into an aluminum crimp connector. We’ve all seen them.

The eyes on Non-Stop cables are actually untwisted, rewoven back together around a stainless steel thimble, and swaged in a stainless collar. In the trade, this is known as a “flemished” eye. It gives maximum strength and lasts the life of the cable.

The other end is welded into a ball to create a solid end that won’t fray.

This attention to quality and detail is what makes Non-Stop the number one brand of elevating scaffolding.

Meet Jay Carey

Jay, and ONLY Jay, has assembled and rigged every Non-Stop Heavy-Duty winch since 2005.

There are many jobs here that must be done right EVERY time. Rigging winches is a good example. Jay does it right every time, without fail, year after year.

Many of our Non-Stop team members have been with us over 30 years. That’s one of the reasons we can turn out equipment that performs flawlessly for you every day.