(This is the article written by Justin Breithaupt, Jr., the owner of Non-Stop, that was published in December 2018 issue of Masonry magazine.)

We Don’t Have a Manpower Problem, We Have a Production Problem

by Justin Breithaupt, Jr.

One of the most popular events at the World of Concrete is the Fastest Trowel on the Block. You have several teams consisting of one bricklayer and one tender, each building a 30-foot- long 8-inch block wall, as high as they can go, in 20 minutes. Each bricklayer usually lays about 130 block. Then they get an extra 4 minutes to strike the joints. At the end of the build, the wall is judged on quantity, level, plumb, bond, straightness, etc., and the winner gets a big prize.

That’s 130 blocks, laid correctly, in 24 minutes. Can an average bricklayer do that in 4 hours? Easily. Can an average bricklayer do that twice in 8 hours, making 260 for the day? Absolutely! Hold that thought.

Where Did The Bricklayers Go?

For the past couple of years there has been plenty of work, but not enough bricklayers. There is definitely a shortage. When the Great Recession hit, maybe they turned to other jobs, but the sheer number of available bricklayers is way down.

The longterm solution, of course, is to attract young people to the trade and train them, but what do we do right now when we simply don’t have the manpower to do the work under contract? If we have to make do with the number of bricklayers we have now, we simply have to find a way to get more production from them.

Increasing Production is the Way Forward

Increasing production was one of the topics at the roundtable discussion at the MCAA 2018 Midyear Meeting in September 2018 in Austin, Texas. Let me stop here and say, if you aren’t going to the roundtable networking sessions at the midyear meeting and the ones at the annual MCAA meeting at the World of Concrete, you are seriously missing out. The knowledge you gain from your fellow mason contractors during these three-hour brainstorming sessions (on everything from silica to insurance) is completely worth the plane trip and hotel bill. But I digress.

Part of the discussion was about production incentives and how employees of the company were compensated based on bringing a job in faster and under budget. For instance, Kent Bounds of Brazos Masonry discussed how their job superintendents were bonused 10% of the additional profit earned over the estimated profit in a given job. If the superintendent used his skill to manage the job day to day getting more production, and it made $100,000 more than estimated, he got a check for $10,000.

Having been in the masonry business with my dad for many years, using an extremely successful bonus system the whole time, I listened curiously for exactly how their incentive systems worked. Some talked about issuing bonuses at year end depending on the company’s overall profitability that year. Some talked about doing it quarterly. But, they all agreed it is a win-win proposition all the way around. When you compensate your men based on their production, production and profit always go up.

Here is What is Really Possible

What I’m about to say is going to blow your mind and possibly have you questioning my credibility, but it’s true. Please follow along and don’t dismiss this article until you’ve read it through and looked at the tables.

I’m in a position to talk to hundreds of masonry contractors a year, and I always ask them if they use an incentive system. Only about 5% say they do and they are getting incredible production and very high profits. There are mason contractors out there who routinely get 1,600 modular brick and 400 to 500 8-inch block per man per day.

When I ask the 95% if they have ever played with the numbers to see if a bonus system would pay off, they say something like, “My guys are getting paid enough, I can’t afford any more.” or, my all-time favorite myth, “A man is only going to give you so many brick in a day.”

How It Works

The most effective incentive systems rely on one simple truth: We only get paid based on materials in place. The faster the bricklayers lay, the bigger the draw. Theoretically, if the bricklayers lay twice as fast as we estimate, you cut both the job duration and the labor money spent almost in half. Now, if this really happened, you might have to hire a few extra laborers to tend these super-bricklayers, maybe another mixer man, and maybe another forklift operator to deliver the materials, but still, you’re talking about saving a whopping amount of labor.

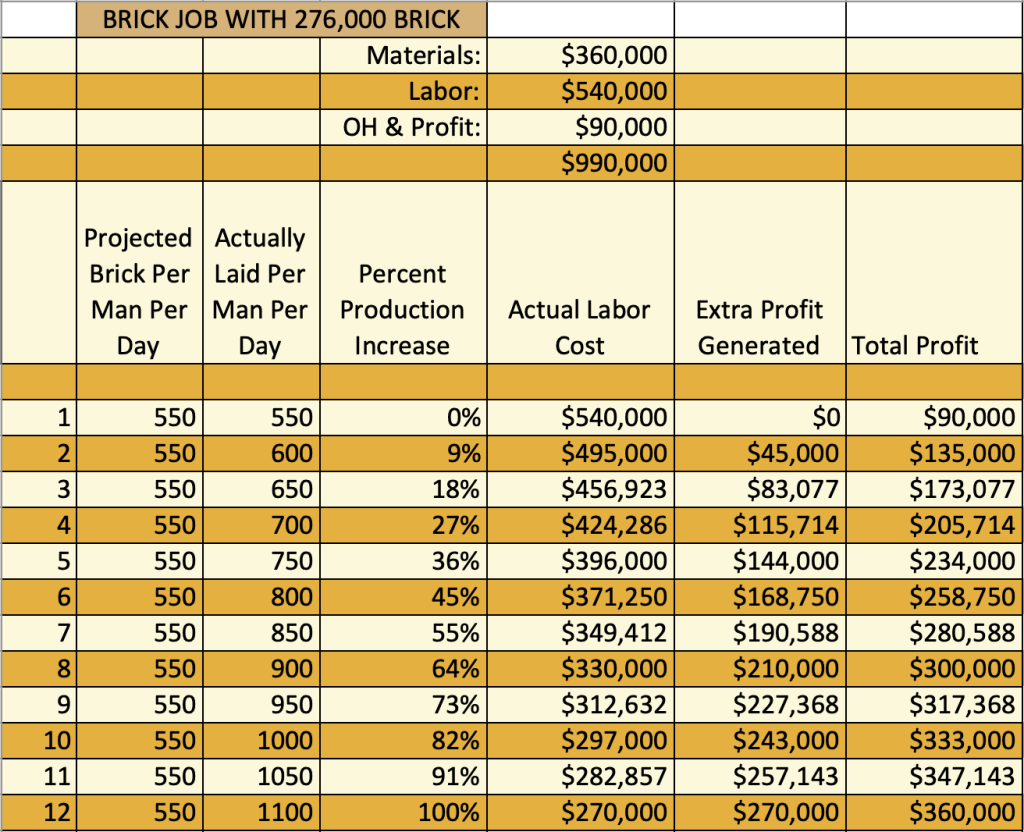

Let’s look at an example of a simple brick job. I polled a few mason contractors in Texas after the midyear meeting and asked them how they estimate their brick jobs. Bricklayers make $25 an hour. They figure they’ll get 550 brick a man a day. They figure brickwork at $13.20 a square foot for labor, and $8.80 a square foot for materials. For a job with 276,000 brick, that’s about $900,000 L&M. Add $90,000 for OH and profit and you’re at a $990,000 bid price.

Now check out the table above. Line 1 shows that if the job goes as planned and the bricklayers lay 550 a man a day, you’ll spend the actual labor money estimated, and make the actual $90,000 profit. Now, just to check the math used in the table, look at line 12. If they lay twice as fast as estimated (1100 a day instead of 550), the job will be over in half the time and you’ll spend half the estimated labor (sure, as above, you won’t cut ALL the labor in half, but fairly close to it). The other half of the labor, something less than $270,000, becomes profit (in addition to the $90,000 profit estimated).

Look at line 3. Adding only 100 brick a day shortens your job duration enough to darn near double your profit. When you start taking small chunks out of the big number – labor, and add it to the relatively small number – profit, you start to see how small reductions in labor turn into huge additions to profit.

How To Do It

It is my personal opinion, based on years of experience, and talking to other mason contractors, the best incentive systems compensate the bricklayers directly. After all, they are the men laying the extra units that put the extra money in the bank. I’m not saying to bonus only the bricklayers, just that the most successful systems always include the bricklayers.

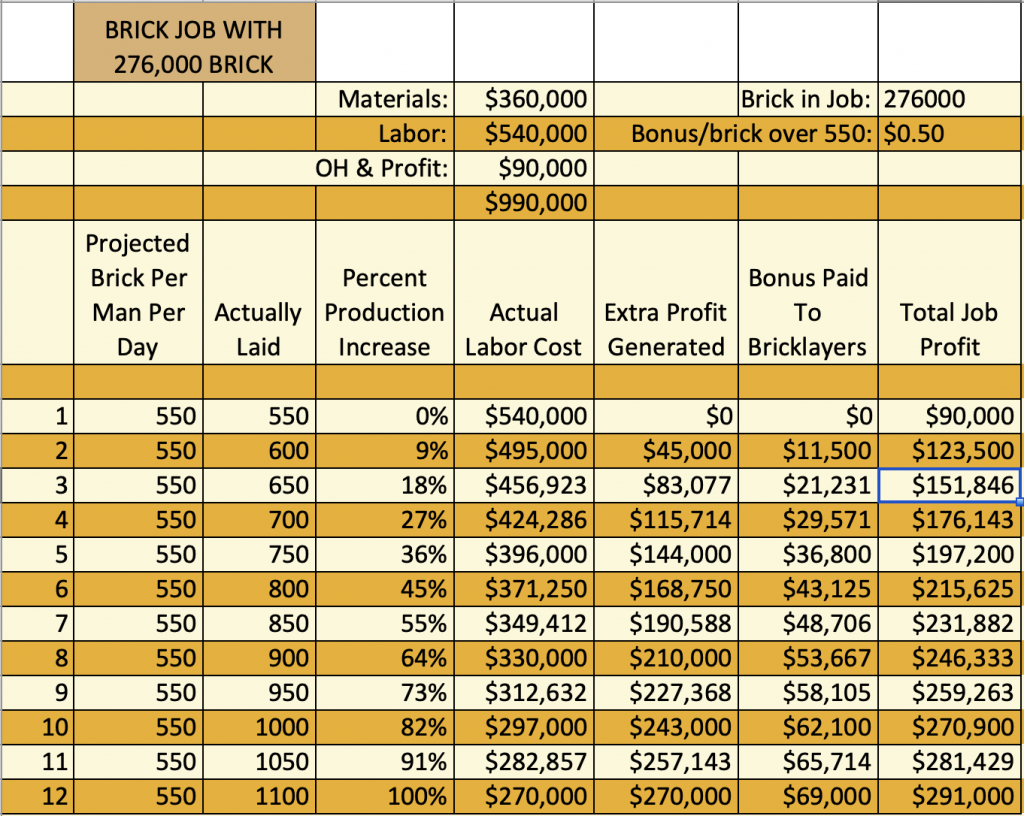

Now, the next logical question is, “How do we get the bricklayers to work faster?” Believe me, they can, remember the Fastest Trowel? The answer is to pay them for extra material over the “breakeven” amount in your bid. In our example job, your labor cost is $1.95 per brick ($540k labor / 276k brick). Give the bricklayers an extra $.50 per brick (or more) above 550 and they will produce like crazy, with no difference in quality. Remember, any time you’re paying bonus, your estimated profit is guaranteed.

Take a look at the same job, now with a bonus system, in the chart below.

This time we give the bricklayers extra money in order to get the higher profit. The bricklayer on line 4 is laying an extra 150 brick a day which makes him an extra $75 a day, in addition to his $200 wages. It’s easy for him. He loves this.

Pay their bonus on a separate check, preferably a different color. I know it’s easier to add it to their regular check, but don’t. This keeps it fresh in their minds that this is additional money they earned by working faster. It will also motivate others who notice the extra check to hone their skills and become a bonus bricklayer.

The Bonus money goes into a weekly pool and it’s divided equally at the end of the payroll week. This is mandatory. Why? Bricklayers live paycheck to paycheck. Telling them to work faster and they will get a bonus at the end of the job, or the end of the year, does not work. You have to pay the bonus weekly.

If they have a week that falls below breakeven, forgive it and move on. Wipe the slate clean every week. If they have a bunch of slow work in a job (like planters in a mall, or bathrooms) you’ll see them start to put all that slow work in one payroll week.

Give Them the Equipment They Need

You can’t get much beyond line 4 on conventional frames. There is just too much bending and stooping, running scaffold-high and moving, and stopping/starting to hop planks, to keep any momentum. Plus, constantly tearing down and re-building conventional frames on a bonus job will eat you alive in labor. Crank-up scaffolding 45 feet high moves from wall with a forklift at the rate of 90 feet an hour. It will save you 85% of the money you’re spending to tear down and re-build frames.

To get past line 4 you need crank-up scaffolding or mast-climbers. Just imagine how many brick a man would lay in a day if he was laying brick on a theoretical straight wall, waist-high, 2000 feet long, and never having to stop. He keeps his momentum. When they are on elevating scaffolding, it’s just like that, and there is a lot less work for the laborers, too – they just crank for three minutes and tend the bricklayers for 20 minutes.

Your New Job Site Culture Will Emerge

I remember back when my dad told his men about his new Bonus System. Even bricklayers who had been with him continuously for years thought he was crazy. It took them a solid month of getting bonus checks to realize it was for real. They couldn’t understand how he could pay them this additional money, so he sat down with any of them who wanted to see the numbers and showed them how if they made $100 in bonus, he made $100 in additional profit (he gave them half of labor saved). So, if a 10-man crew made $100 each in bonus, he made $1000. He was literally splitting his extra profit with them. As a result, they developed a new trust in him.

Morale and loyalty will go up to a new high. They all think they are underpaid – now they’re working for a company who truly pays them what they’re worth. Production goes way up with no loss of quality. They were capable of it all along. This might make you very mad, but shake it off, chalk it up to human nature, and focus on your new-found profits.

Your men will start to solve their own problems – problems that used to kill a lot of your time. They’ll take their breaks on the scaffold, or not at all. Your jobs will run as if you were there all day. Some superstar producers will emerge who match their paychecks with bonus checks and insist on working together. Accommodate them. It will snowball.

Any new bricklayer who doesn’t produce usually won’t last a day on a bonus job. The men on the wall will tell the foreman to get rid of him at the first break (because that man is costing them money). You will hear about it before lunch when the foreman calls in for the new man’s check.

If you need more bricklayers, your men will get them for you. They will bring you bricklayers who are faster than they are (so they don’t drag the count down). If you have to lay some men off, they will always come back when you get more work because you pay more than anyone else. They will leave where they’re working and come back to you.

Tips And Tricks

They will develop tricks to work more efficiently. For instance, our bricklayers only cut their mortar off once. They got enough to throw a head joint and kept moving. They got the rest with their jointer as they struck the joints.

Some bricklayers gave the laborers a little money each day to strike up and hand them brick. When we went non-union, we hired guys to do that, especially summer help. Many of them came back to learn to lay brick with us because we paid so well.

You can break the job up into categories of work. On a school job, for instance, you’ll set up one crew with a different breakeven for the inside corridor block walls, and a different breakeven for the crew on the exterior brick.

Maybe This is How We Perpetuate the Trade

I truly believe that companies who adopt a performance-based pay system can use it to attract new apprentices to the trade. If bricklayers become the highest paid trade, we can assure a steady supply of manpower for the future.

Follow-Up on the Bonus Article

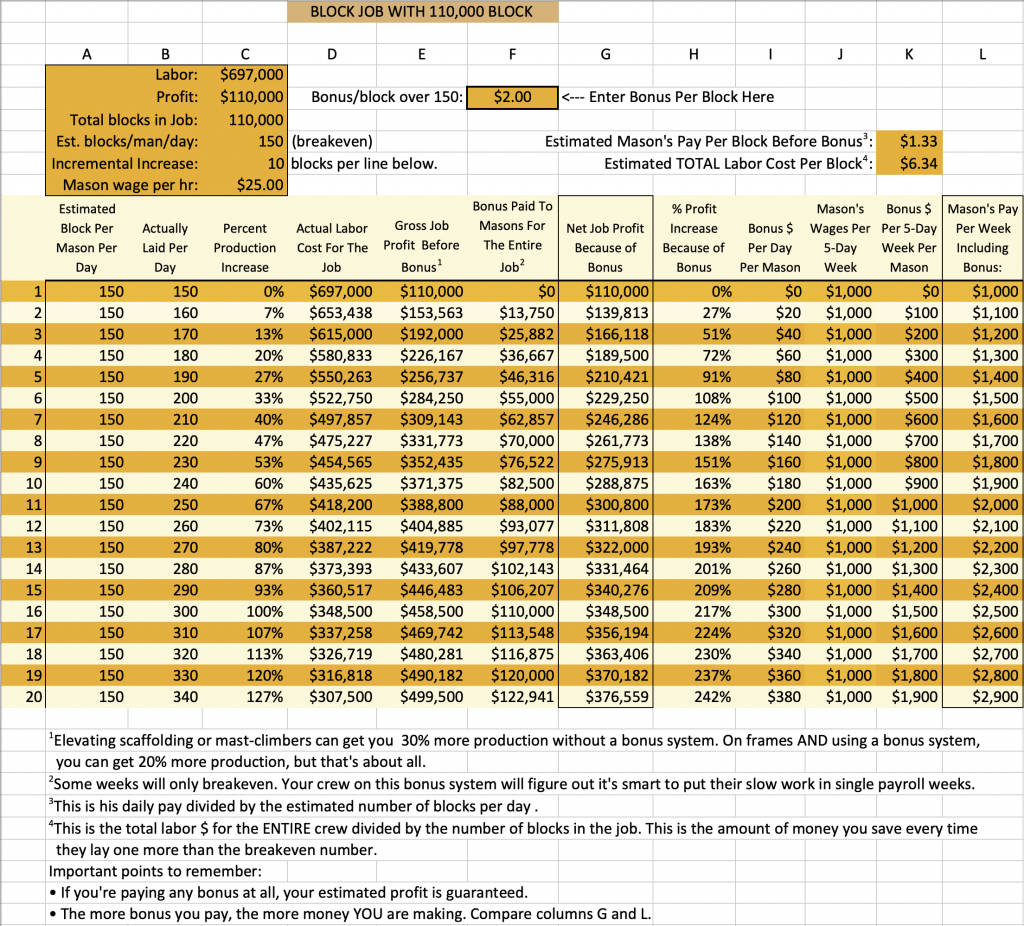

Since the publication of the original article, I’ve been asked many questions about the finer points of the bonus system we used in the masonry business. Many of the questions were about the specific effect on the mason’s check. The table below now has a column showing the effect on a single mason’s check. This table is for a BLOCK job.

This example shows a block job with the bonus set at $2.00 per block. To really get the masons’ attention, you can tell them, “I’m actually paying you $1.33 for every block you put in the wall. If you move a little faster, I’ll pay you $2 a block for every block you lay over 150 a day, averaged over a week.” (You’re actually saving $6.34 per block.) This WILL get their attention. After seeing a few bonus checks, you’ll be amazed at the extra production. This is how some mason contractors, using elevating scaffolding (or mast-climbers) are getting 400 to 500 8-inch blocks per man per day. If you’re unsure of $2 a block, start at a dollar. You can always increase it.

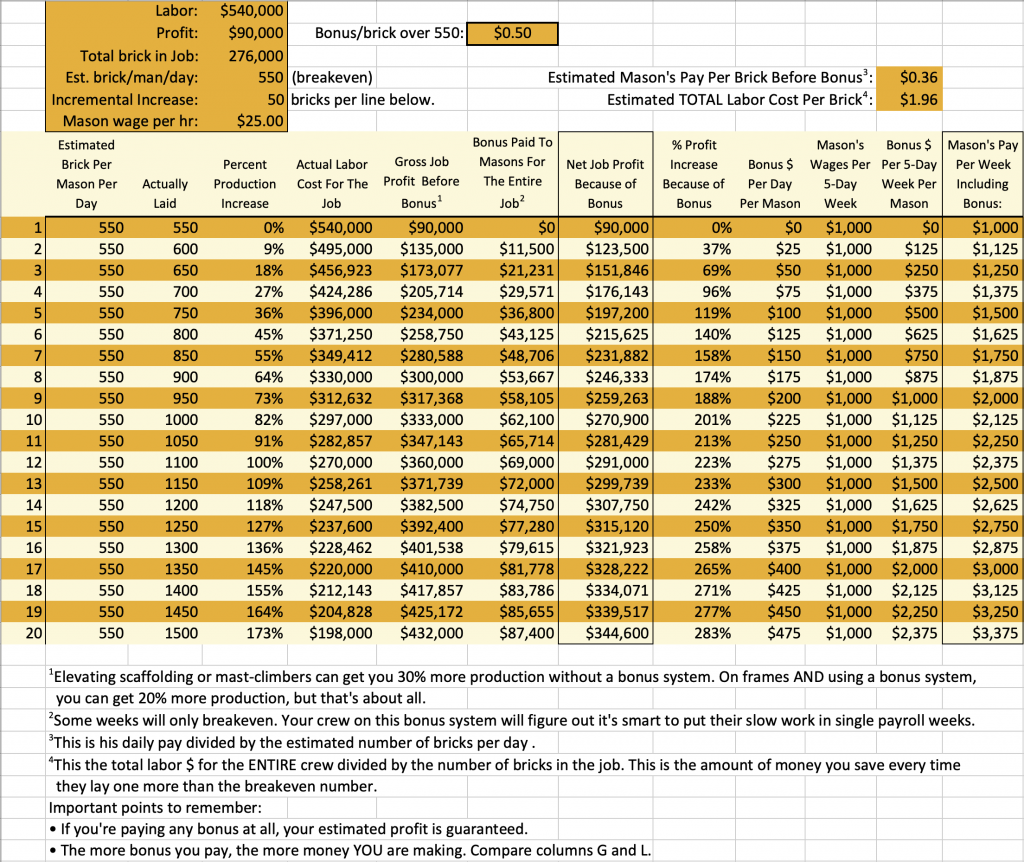

The chart below is a variation of the brick job in the article:

This example shows a brick job with the bonus at $0.50 per brick. To really get the masons’ attention, you can tell them, “I’m actually paying you $.36 for every brick you put in the wall. If you move a little faster, I’ll pay you 50¢ a brick for every brick you lay over 550 a day, averaged over a week.” (You’re actually saving $1.96 per brick.) This WILL get their attention. After seeing a few bonus checks, you’ll be amazed at the extra production. This is how some mason contractors are getting 1200 to 1500 brick per man per day.

We made hundreds of thousands of dollars every year with this system. If you would like more information about the system, feel free to call me at Non-Stop Scaffolding at 318-222-0702. If you have a job coming up, I can run your numbers through this spreadsheet and email you the results.

– Justin Breithaupt, Jr. 318-222-0702